The replay machine has to be regularly maintained to avoid quality loss in the transfer process, and to prevent possible damage of the tape due to mechanical misalignment of the equipment. All transfer equipment has to operate within the specifications.

HOW:

Besides routine cleaning (as described in step 2.3.), the machine has to be degaussed regularly (recommendation: every 8 hours of operation). To avoid signal distortions from magnetised parts, demagnetise heads and tape path by using a degaussing choke.

To avoid possible damage, observe the following points before de-gaussing the machine:

- Switch off the machine!

- Remove all magnetic tapes and place at least two metres away from the machine and the de-gausser!

- Only switch the degaussing choke on and off when it is at least one metre away from the machine!

SEE:

John G. MacKnight: Demagnetizing A Tape Recorder

Ray A. Rayburn: Cleaning and demagnetizing tape recorders and duplicators

The Practitioners Guide - Analog Tape Machine Alignment

Operation manual of Studer tape recorders

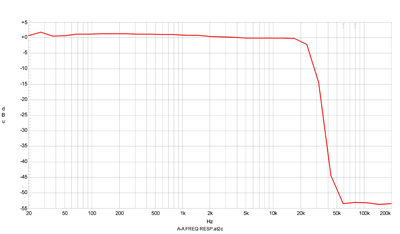

Frequency response of a tape recorder aligned within specifications